NOC studies feasibility of hydrogen energy in Nepal

NepalPress

NepalPress

KATHMANDU:

While Nepal Oil Corporation has started a study to look at hydrogen’s feasibility as energy storage, it plans to evaluate hydrogen production, marketing, and export. Hydrogen fuel cells have already seen intense research worldwide. Still, they are yet to see widespread commercial adoption, especially in a cost-effective way.

Nepal Oil Corporation (NOC), which has been importing, storing, and trading petroleum products, has taken the lead in this field to produce, consume, and export hydrogen, which is considered an essential source of clean energy in the future.

NOC Managing Director Surendra Poudyal of the corporation said that the corporation has planned to start work immediately on the energy sector’s future, as reported elsewhere.

“The world has come a long way in terms of hydrogen. The corporation has started working without delay to use this technology and promote clean energy,” he said. “If we don’t understand that hydrogen is a strong and good source of the future, we may fall behind.”

WHY NOT BIO-METHANE?

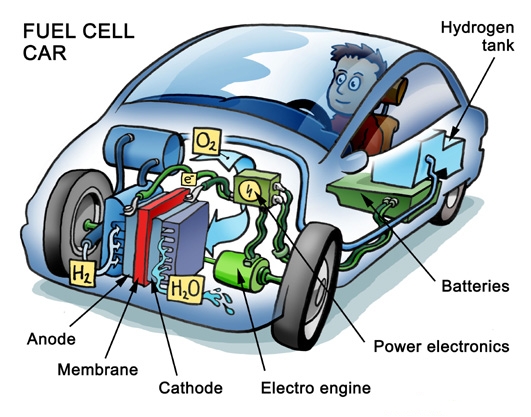

The concept behind hydrogen is energy storage, and the current technology for hydrogen utilization is hydrogen-based fuel cells that are neither cheap nor widely available. The production of hydrogen is relatively energy-intensive compared to Methane, which can be made easily in Biogas reactors

Elon Musk’s company SpaceX is working seriously on methane-based rockets. The current technology of Bio-methane production also has seen massive leaps in terms of purification to CNG standards. This technology is already available in Nepal to some extent. CNG engines are relatively clean burning and cause fewer emissions. With affordable emission mitigation technologies, CNG engines are the easiest to convert to Ultra-Low Emission Vehicle mode.

While Bio-Methane/CNG can be easily manufactured from animal dung, nightsoil, kitchen and agri-waste, with recent scientific developments it is also possible to use less bio-degradable raw materials like saw-dust, wood residue, paper to Bio-Methane through intermediate pathways. Developments in plastic waste processing like pyrolysis can also be harnessed in this direction to make CNG as the final end product of all these technologies. As per expert estimates, any country’s total fuel bill can be obviated by such an advance. Bio-CNG is the perfect partner of solar in rural electric grids since Bio-CNG can take care of night time electric loads.